|

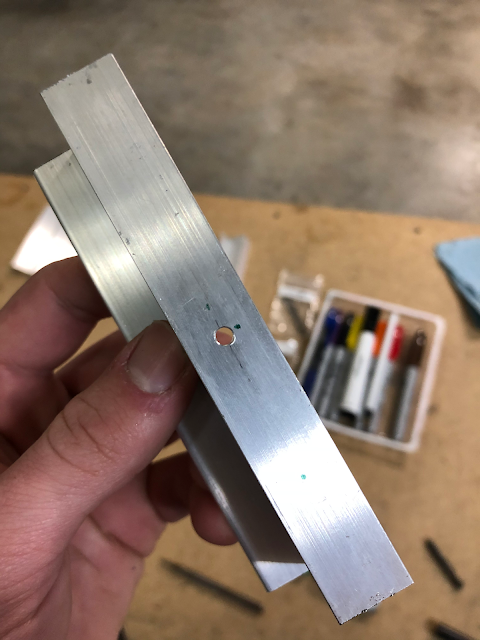

| Yep, that's the cutout from when I made the leading edge cradle. Works perfectly! |

After clecoing the skin at the nutplates, I was showing almost a 1/16" gap between the leading edge and fuel tank skins. Instead of immediately freaking out I decided to see what the gap would be like once the ribs were in place too since they'll probably affect this.

The lower part of the skin is actually perfectly aligned, which means the top part can't be far off.

Since the baffle appears to be in a good position I took the fuel tank skin off and started clecoing the ribs in place, marking them with a sharpie as they went on so I could keep them in order later. One thing I made sure to do was to attach each rib only to the baffle at first since most of the center holes had to be elongated to match the brackets underneath. Clecoing the ribs to the center holes would cause every other hole in the baffle to be elongated to match, which is far from ideal.

|

| Don't drill it like this! |

With the ribs clecoed only to the baffle for now, I got the 12-inch #30 bit and got to work, drilling and clecoing the baffle to rib holes first before match drilling the rest of the holes into the rear baffle and brackets underneath. A drill stop is absolutely a must here to avoid damaging the spar below. For the inboard ribs I had to use a scrap piece of aluminum to protect the spar, which lies less than an inch under the baffle and would be very easy to damage even with a drill stop in place.

Eventually, all ribs were drilled and completely clecoed to the baffle and brackets.

|

| Perfect alignment! |

Before putting the skin on these fine ribs, I match drilled all of the stiffeners to the lower skins. I then immediately took them off, since I won't have enough clecos to leave them attached and also have the skins on the ribs. It's mind boggling that even with all of the clecos I've collected (I think I have around 600 clecos total at this point? I don't know, I've lost track) I still won't have enough. Oh well.

To fasten the skins to the ribs is once again a lesson in patience and finesse. The skin is, as I have come to learn with these prepunched kits, extremely tight to the ribs around the leading edge. A fair amount of carefully-directed force is needed to get the first few holes fastened properly, but the rest are cake once these are taken care of.

|

| A quick teaser... |

|

| A wing! |

Upon closer inspection, the gap between the fuel tank and leading edge skins did in fact get smaller. The first bit of drilling to be done is putting #19 holes into the joint plate so the tank skin can be secured with screws and nutplates here.

From there it was reaming and drilling just like on the leading edges, except there's a lot more holes this time. Once done, the tank and brackets were unbolted and unclecoed from the spar in one piece to be placed in the cradle. Progress!